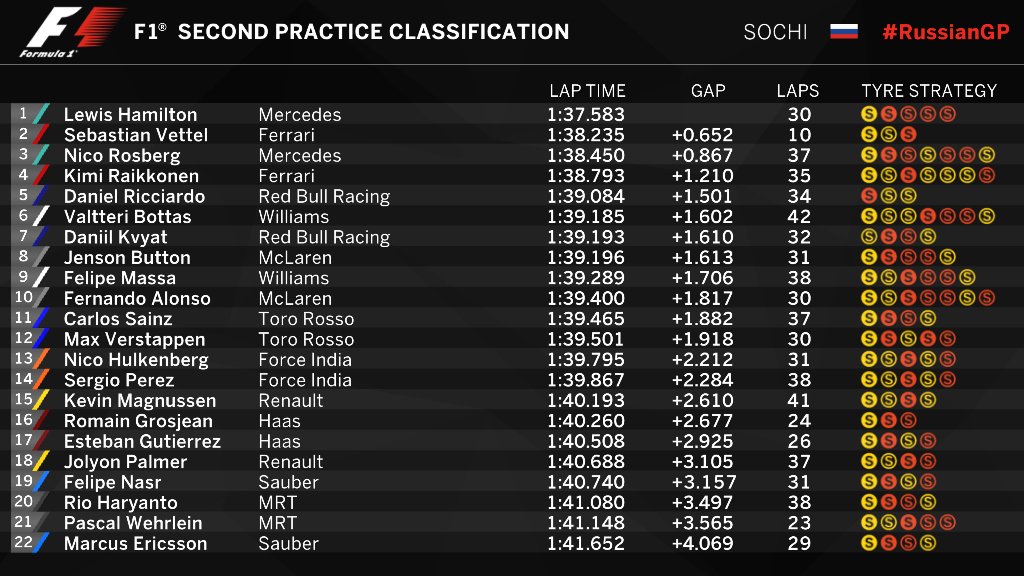

Tại Sochi Fer cũng nâng cấp cánh gió mới tăng Downforce. Không biết gói nâng cấp động cơ lần này của Fer có liên quan đến hiệu suất đánh lửa phản lực không? e mới đọc bài này nhưng nó nặng đô về kỹ thuật quá không hiểu được.

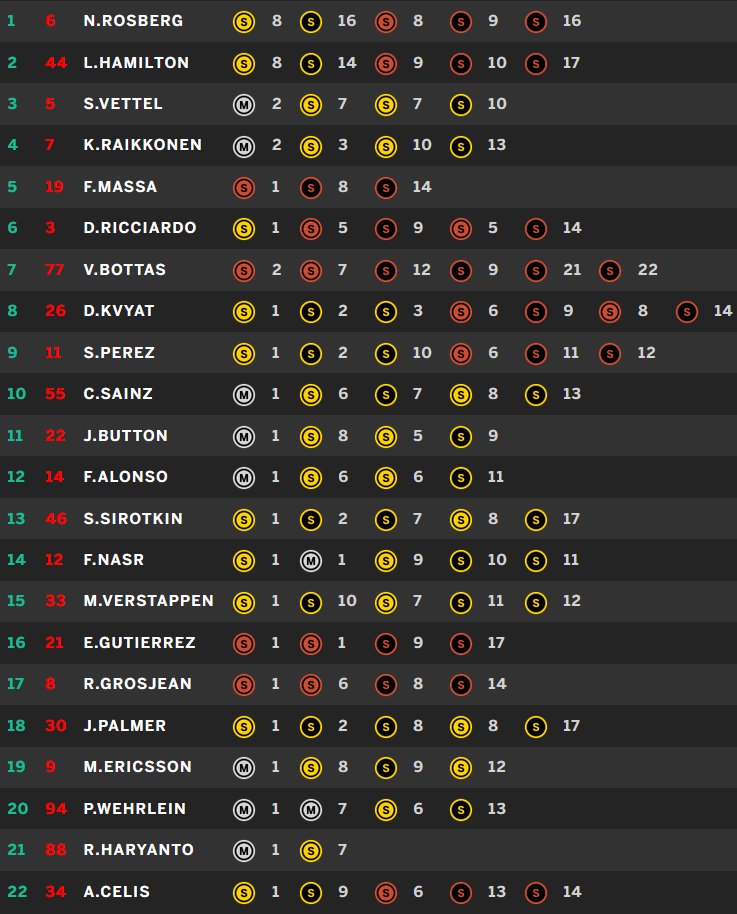

Đọc lại Fer đã dùng ở Canada từ 2015

Turbulent Jet ignition pushes engine combustion efficiency

Turbulent Jet ignition pushes engine combustion efficiency

It has recently emerged that Turbulet Jet Ignition (TJI), and not HCCI, is one of the key technologies that Scuderia Ferrari is using in Formula One engines to push the power unit's efficiency further forward.

Confirmation has come from Mahle, one of Ferrari's suppliers, that at least the Italian team is now using TJI in its power unit. The company's latest annual report quotes Fred Turk, head of Mahle Motorsports as saying: “The Mahle Motorsports engineers have found the right solution for Scuderia Ferrari. More than five years of development preceded that crucial phone call to Maranello with the proposal: ‘We’ve found an interesting new solution for you.’ Mahle Jet Ignition is the name of the innovation that gives the engines from Maranello a boost. Within a few weeks, in spring 2015, we adapted our solution to the Formula 1 requirements, allowing Ferrari to compete in Canada with this solution for the first time.”

Since the Canadian Grand Prix of 2015, in which Ferrari was reported to have made a solid step forward, Mahle's new Jet Ignition system is in use to improve combustion efficiency, and as such power - given that Formula One regulations currently limit performance by limiting the amount of fuel that can be used.

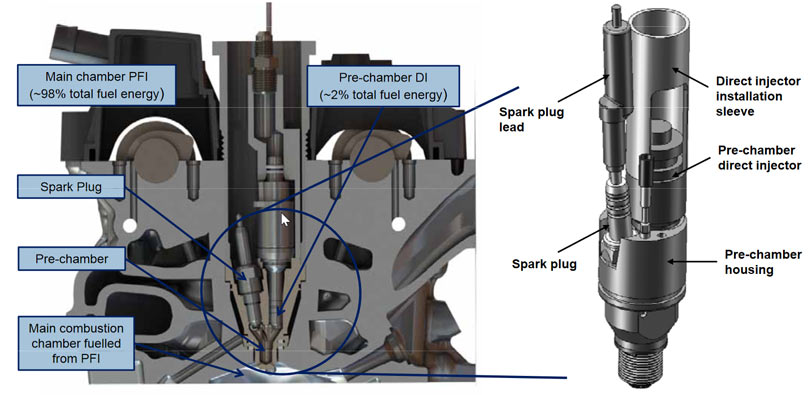

The jet ignition system is a new combustion technology, patented as US20120103302 on 1 Nov 2011 that replaces the standard spark plug in SI engines with a jet ignition chamber assembly. It facilitates the implementation of ultra lean-burn operation in gasoline engines, improving their efficiency and reducing the formation of pollutants such as nitrogen oxide and particulates.

One of the main benefits of the system is that, depending on the specific design of the cylinder heads, the jet igniter can be a drop in replacement for the traditional spark plug.

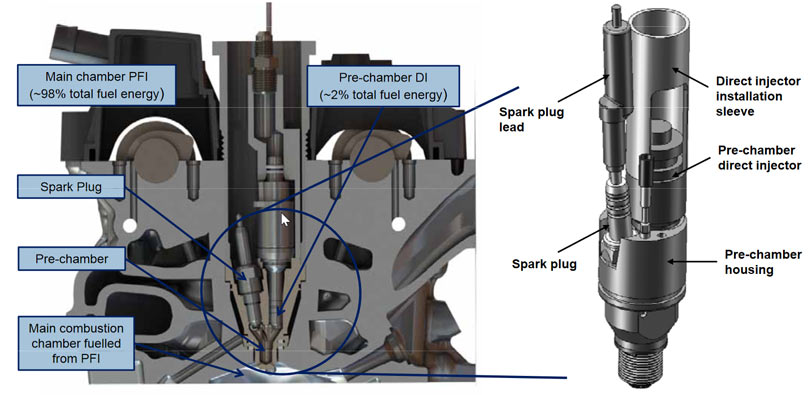

The jet igniter itself includes a small ignition chamber with a direct injector (DI) that provides a small amount of auxiliary fuel (<5% of the total system fuel) and a spark plug to ignite that charge. The ignition chamber is connected to the main chamber by a number of orifices which allow jets of partially combusted products to ignite the main charge. The smaller orifice size causes turbulence in the hot gas jets which then penetrate deeper into the main combustion chamber and cause an evenly distributed ignition effect. The main chamber is fuelled through a conventional port or direct-injection injector.

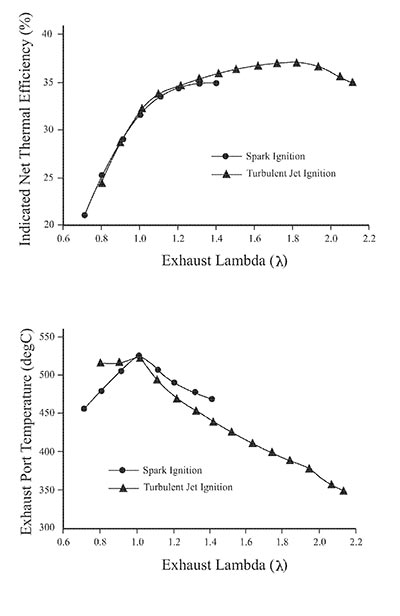

With 4-8 ignition jets, depending on the application, the main charge is extensively ignited and a faster burn-through and pressure build-up is generated. Furthermore, this process allows increased compression ratios (a 4 point increase in some applications) combined with lower combustion temperatures and reduced throttling / pumping losses to achieve peak indicated thermal efficiencies up to 45% - not to be confused with the reported > 48% thermal efficiency that Mercedes is achieving for its entire F1 power unit.

The details of how Mahle has adapted the TJI system for Ferrari or obviously still held anxiously secret, but results from the various testing beds have shown promising measurements. Mahle have for instance tested various prototypes with on a visual test bed, as well as a single-cylinder engine, and found fuel efficiency gains of more than 17% over spark ignition. Apart from this increased efficiency, the potentially reduced cooling needs will be equally interesting for F1 designers, as that could allow tigher cooling packages and improved aerodynamics.

Mahle says the new design results in much quicker ignition that with standard spark ignition, "enabling the engine to operate at optimum spark timing as the knock limit is extended significantly. In car engines, high fuel savings are achieved by the higher, almost diesel-like efficiency. Engine tests show specific consumption below 200g / kWh and significant related reductions in CO2 emissions".

The German powertrain designer also states that in addition to providing efficiency and fuel consumption advantages, the system also brings considerably reduced emissions, with a reduction of NOx emissions by more than 99 percent in ultra-lean mode. The latter is obviously less relevant for Formula One and the Scuderia, but certainly interesting for future mass market exploitation as emission norms become more and more stringent.

By Steven De Groote on 25 Apr 2016, 23:37